PROCESS AUTOMATION

Process Automation is a core area of our business at Closoft and our expertise has been build over two decades of serving customers in many industries. Our main objective is to make technology available to our customers in order to assure their safety, increase their profitability, and promote sustainability. We work hard to comprehend your processes, requirements, and challenges so that we may serve as your trusted consultant. We always assure a safe and effective process owing to our in-depth knowledge of process control and the interdependencies of the factors that affect your equipment. We deliver outstanding client care and solutions in a combination of means, from embedded resources to fixed-cost turnkey projects, thanks to our cross-platform experience and vendor neutrality.

Water and Waste Water

We understand the economic, regulatory, and technical needs that impact

the water and wastewater industries, from the automation of drinkable water to wastewater

treatment. Our extensive knowledge in product application, engineering, project management,

system commissioning, and training stems from years of operation and numerous installations

from Closoft.

- Wastewater Effluent Monitoring systems for Industries.

- Smart Water Network Management.

- Water Quality Monitoring for Potable Water.

- Municipal wastewater Treatment Plants.

Oil & Gas

Closoft offers integrated automation and engineering services for

upstream, midstream and downstream applications in the Oil & Gas industry. Closoft can

collaborate with your engineering, operations, and field service teams to design, program,

start-up and support PLC and DCS control systems at the heart of your process. Closoft has

developed solutions that will increase efficiency, decrease risk and provide higher yields

and ultimately a higher degree of automation at your facility.

- Oil refinery optimization

- Predictive Maintenance in Oil & Gas

- Natural Gas Liquefication Process

- Metering & Instrumentations

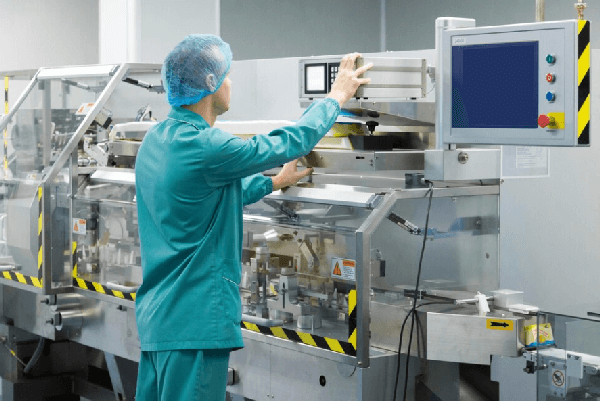

Food & Beverages

Constant demand for consistency in product quality and taste makes Food

& Beverage a demanding industry. Complexity increases as ever more stringent hygiene

regulations for food safety add cost pressures. Closoft has been helping Food & Beverage

producers meet various challenges through the design and integration of automation, control

and information systems. Our solutions have a direct and immediate impact on material,

labour and energy costs to help our customers improve throughput, minimize downtime,

streamline production processes and ultimately ensure the highest quality of products.

Our Engineers collaborate and work with your Engineering and Maintenance teams to provide

solutions that are easy to maintain and compliment your existing systems and engineering

standards. We know that uptime and throughput are essential for plant profitability, in

addition to sanitary design to increase food safety compliance.

- In-line Quality Control

- Hygienic Design Solutions

- Edible Oil Refining Process

- Instrumentation & Water Treatment Standardization

Pharmaceutical

Today’s thriving biopharmaceutical industry demands high productivity

and efficiency balanced with meticulous alignment to GMP standards.

In our consulting and implementation efforts, we carefully analyze and consider ease of use,

operational costs, quality control, cost-effectiveness and digital capabilities which are

some of the factors that should ideally be considered when choosing pharmaceutical mixing

equipment and processing solutions.

- FDA 21 CFR Compliance

- Data Analytics

- Remote Monitoring & Report Generation.

- Process Instrumentation & Analysers