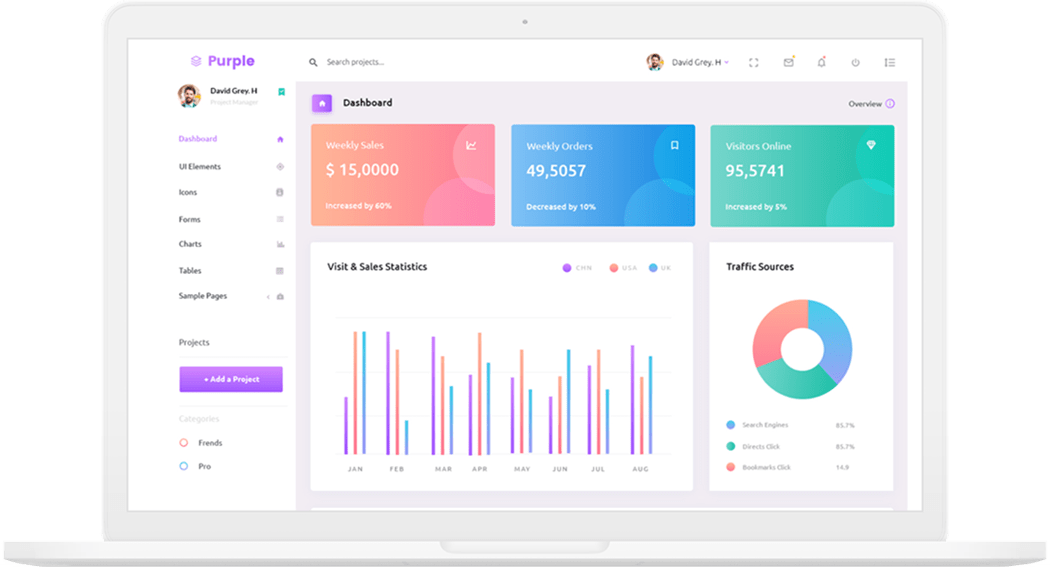

Get the best out of your business with our innovative software & web solutions.

Webschedio India Private Limited is a leading Web Development, Software Development company in India.

We provide a wide range of creative and technical web Solutions including Web design, web development, sofware solutions, android application development, IOS application development, website hosting, Digital marketing and SEO services. Whether it is developing a successful E-Commerce store, creating a corporate online presence, Web experts assist you in achieving your goals from the simplest static site to full-blown content managed enterprise solutions.

Our web Designers and Developers are dedicated to producing quality business websites. We offer a full web service, which begins with design and carries through to Internet Marketing, SEO, and beyond.

Learn moreRead More

A professional, creative and unique design that fits into all the screens from mobile to large screens.

Custom business software solutions to meet the clients requirement for running the organization hasle free.

Mobile App plays an vital role in all kind of business environement. We provide outstanding mobile applications...

A businesses can be made to rise with better ecommerce solutions and well-designed application

Register your prefered domain and get the most reliable hosting instantly with leading customer support

SEO acts as the lucrative tool to internationalize your website and increase the on-site and off-site visitors

SwiftQ is designed to simplify and streamline the management of patient queues in hospitals and clinics. It helps reduce waiting time, improve patient experience, and enhance operational efficiency. Patients can register and receive a token number, while the system automatically organizes and updates the queue in real-time. Staff and doctors can monitor the queue status, call the next patient, and manage appointments seamlessly.

Learn moreRead MoreAutosnehi is mainly to create long term value for society in terms of safety and security of auto travelers in the city. Web application, Digital display card and radium stickers with unique numbers for auto-rickshaw will help the Traffic Department and auto rickshaw Union.

The Digital display card will be displayed behind the driver seat and it contains full details of driver/owner of particular auto rickshaw and with unique system of QR code linked to Autosnehi web page this helps in elimination of duplication or misusing of the display cards.

A passenger can scan this QR code through their mobile and find the details of driver/owner in Autosnehi web page. And he/ she can share these details with their Parents/ relatives / Guardians and can be confidently travel without any fear of unknown driver details.

Learn moreClick here for more details

"Home sample collection" typically refers to a service provided by various healthcare organizations or laboratories wherein they arrange to collect samples from patients at their homes instead of requiring them to visit a healthcare facility for sample collection. This service is particularly beneficial for individuals who are unable to travel due to illness, disability, or other constraints, as well as for those who prefer the convenience and privacy of having samples collected at home. Our application has been designed to serve the needs of healthcare organizations or laboratories as well as the patients.

Key features are and not limited to:

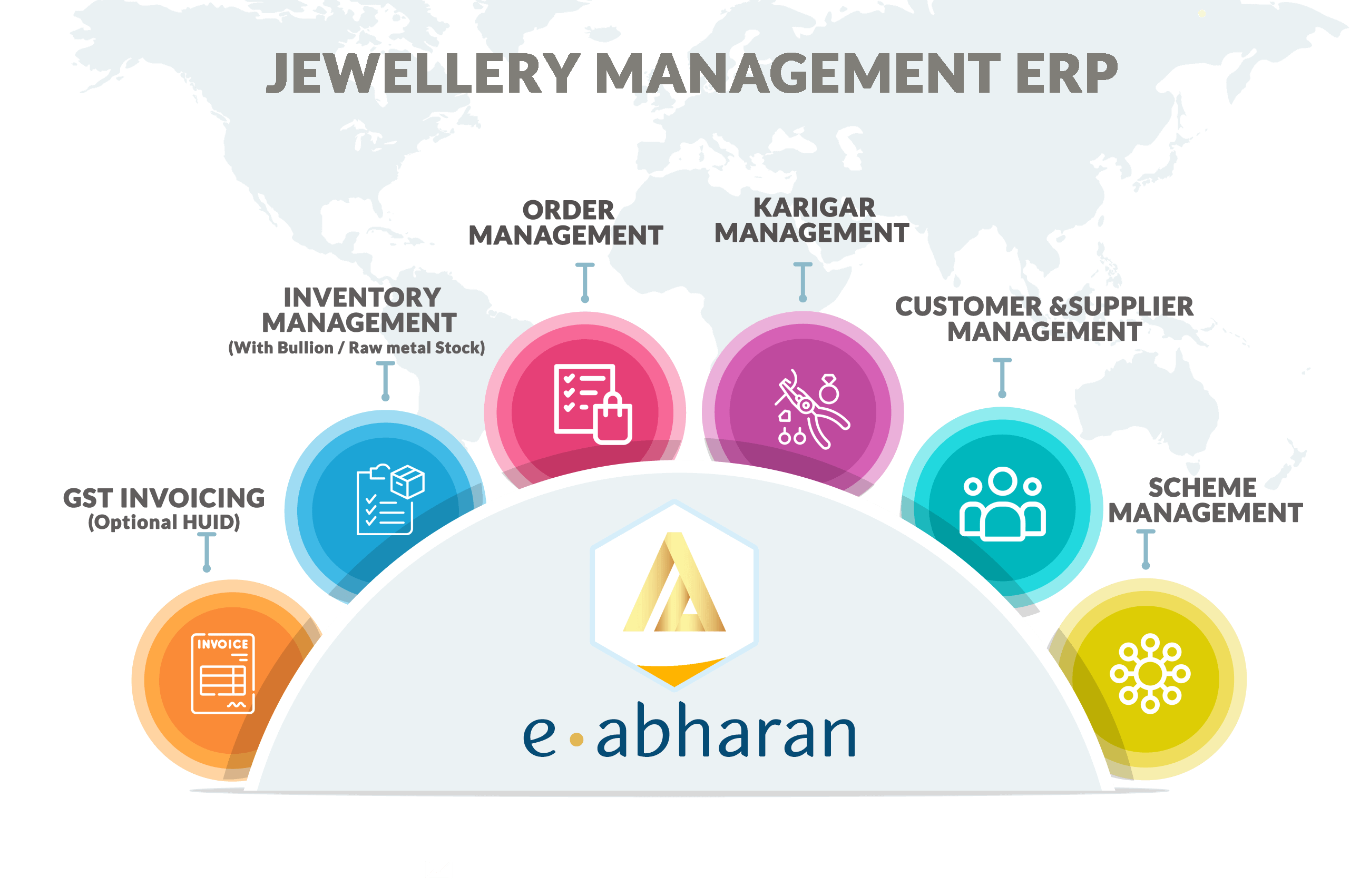

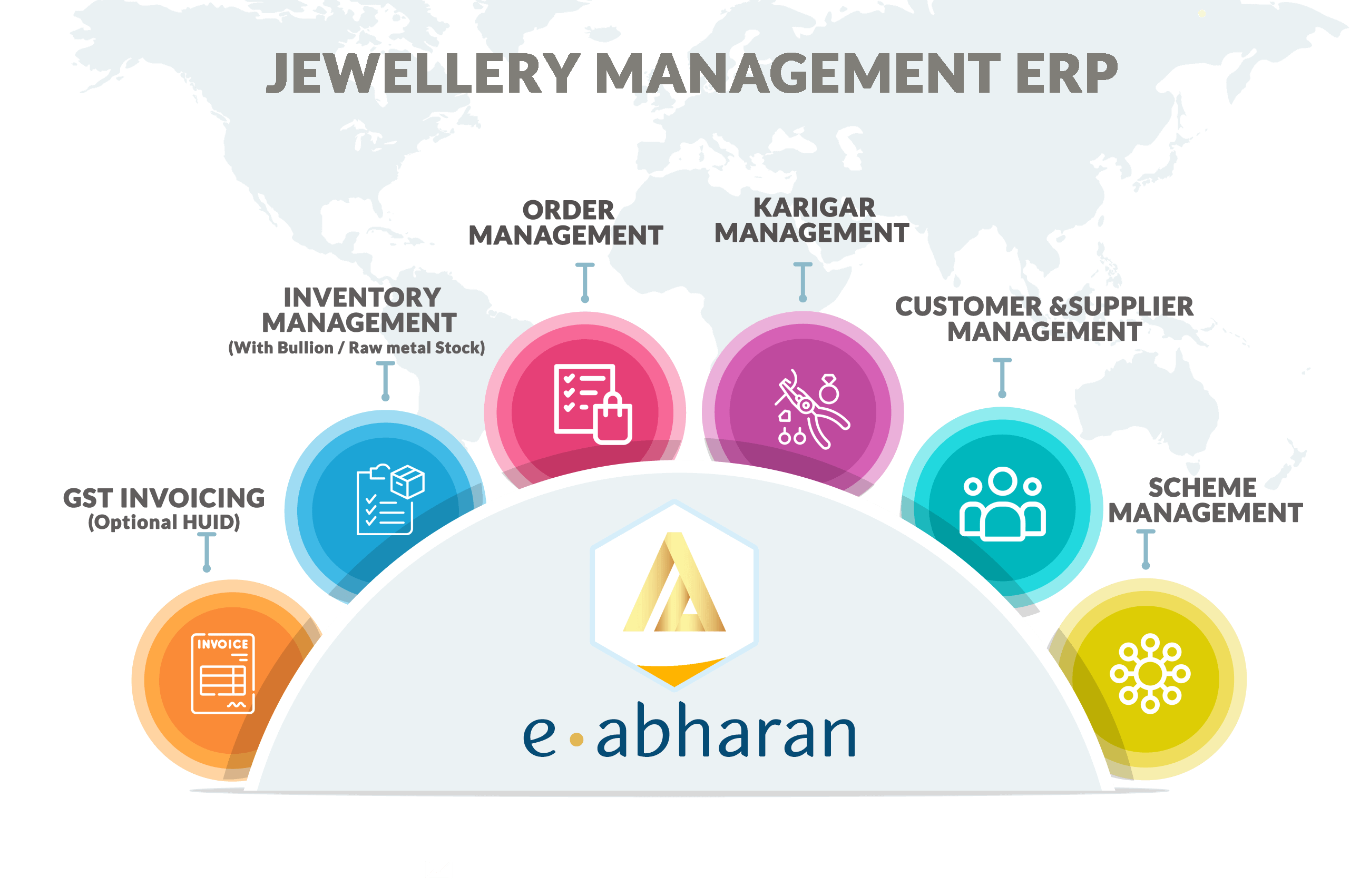

A jewelry software plays a crucial role in streamlining operations, improving efficiency, and enhancing the customer experience in the jewelry industry. By leveraging advanced features and functionalities, businesses can stay competitive and adapt to the evolving demands of the market. Our Jewelry software, e-Abharan is just made for that. It addresses the unique needs of businesses operating in the jewelry industry. This software encompasses a range of functionalities to streamline various aspects of jewelry business operations, from inventory management to sales and customer relationship management.

Enquiry

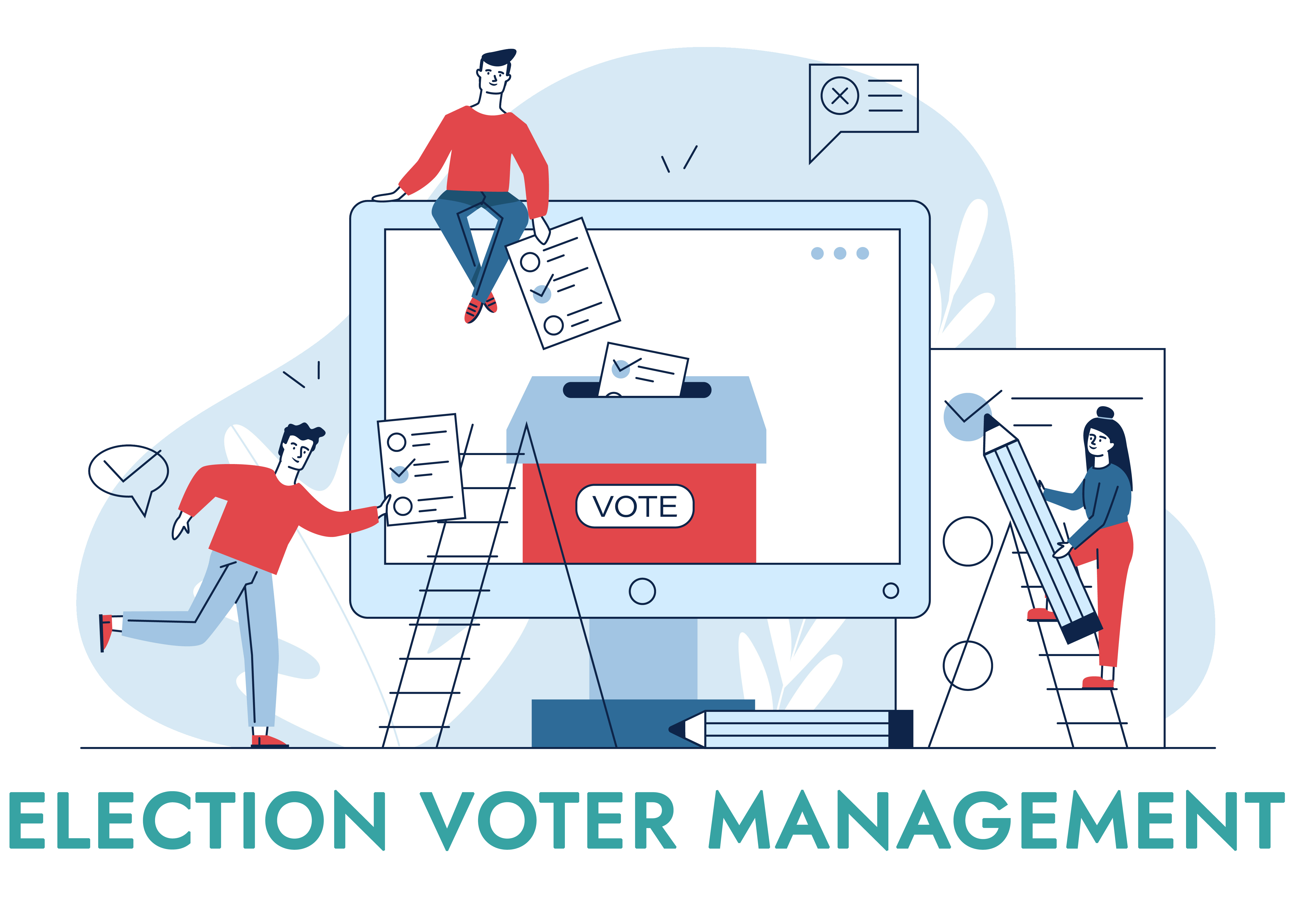

Our Election Voter Management System (EVMS) software is designed to streamline the process of managing voter data, registration, and election-related activities. Our application gives a great opportunity to go close to the voter one final time before the elections and showcasing them how meticulously a candidate prepares for an election.

Key features are and not limited to:

Foundry ERP (Enterprise Resource Planning) software is a comprehensive solution designed to streamline and integrate various business processes within a manufacturing foundry environment. Foundries are industrial facilities where metal casting processes are carried out, typically involving melting metals and pouring them into molds to create complex shapes. The primary objective of Foundry ERP software is to optimize operational efficiency, enhance productivity, and facilitate informed decision-making across all functional areas of the foundry.

Learn moreEnquiryAutosnehi is mainly to create long term value for society in terms of safety and security of auto travelers in the city. Web application, Digital display card and radium stickers with unique numbers for auto-rickshaw will help the Traffic Department and auto rickshaw Union.

The Digital display card will be displayed behind the driver seat and it contains full details of driver/owner of particular auto rickshaw and with unique system of QR code linked to Autosnehi web page this helps in elimination of duplication or misusing of the display cards.

A passenger can scan this QR code through their mobile and find the details of driver/owner in Autosnehi web page. And he/ she can share these details with their Parents/ relatives / Guardians and can be confidently travel without any fear of unknown driver details.

Learn moreClick here for more details

"Home sample collection" typically refers to a service provided by various healthcare organizations or laboratories wherein they arrange to collect samples from patients at their homes instead of requiring them to visit a healthcare facility for sample collection. This service is particularly beneficial for individuals who are unable to travel due to illness, disability, or other constraints, as well as for those who prefer the convenience and privacy of having samples collected at home. Our application has been designed to serve the needs of healthcare organizations or laboratories as well as the patients.

Key features are and not limited to:

A jewelry software plays a crucial role in streamlining operations, improving efficiency, and enhancing the customer experience in the jewelry industry. By leveraging advanced features and functionalities, businesses can stay competitive and adapt to the evolving demands of the market. Our Jewelry software, e-Abharan is just made for that. It addresses the unique needs of businesses operating in the jewelry industry. This software encompasses a range of functionalities to streamline various aspects of jewelry business operations, from inventory management to sales and customer relationship management.

Enquiry

Community-based membership registration software is designed to facilitate the management of membership data, communication, and engagement within communities, organizations, clubs, associations and similar groups. Whether it's a neighborhood association, a sports club, a professional organization or a non-profit community group, this type of software helps streamline the membership registration process and fosters community interaction.

Community-based membership registration software helps organizations effectively manage their memberships, foster community engagement, and enhance the overall member experience. By leveraging advanced features and functionalities, communities can strengthen their connections, increase participation, and achieve their goals more efficiently.

Learn moreEnquiryIn today’s world an institution without a website lacks a major identification and doesn’t win students’ and their parents’ trust and belief. Pronouncing the abilities of an institution can be easily done using a website. The outlook of the website, its contents and its appeal becomes a major enticing factor to attract more students who can experience the best education and infrastructure the institution is offering.

In the same time, if the website becomes a dynamic one, every single update can be pushed instantly onto the web page and can be made available to all the viewers instantly. The institution themselves can push all new updates, events, photo gallery everything from their side without involving a service provider.

We offer you a very user friendly dynamic website for your institution!

Learn moreEnquiry

Our service provides statistics on opens and clicks so you can monitor the results and improve your email campaigns.

Increase sales and customer satisfaction with smarter SMS campaigns, instant OTPs, notifications, surveys & more

Our Voice Broadcasting campaign fits in all your needs and business requirements