FACTORY AUTOMATION

Our Factory Automation section specializes in intricately engineered, integrated systems and solutions, ranging in scope from small, standalone projects to large, turnkey operations. It can be challenging to determine which direction to go in as Industry 4.0 trends, artificial intelligence, and machine learning technologies proliferate throughout the industrial control environment. The performance of your automation and controls infrastructure depends on choosing a system integrator who not only comprehends these technologies but also fully truly understands your process and goals. In order to achieve this evolution, we at Closoft adopt a hands-on approach to assessing your present state while collaboratively creating an ideal future state, roadmap, and prioritised set of actions.

Asset Management – Traceability

Automation in asset management traceability revolutionizes how organizations track and manage assets throughout their lifecycle. By leveraging technologies like RFID, barcodes, IoT sensors, and automated data capture systems, organizations can ensure real-time visibility into asset location, status, and maintenance history. Automated workflows streamline processes such as asset requests, approvals, and transfers, while predictive maintenance capabilities optimize asset uptime and reliability. Whether you manage physical equipment, digital assets, or both, our automated solutions optimize operations, reduce costs, and enhance decision-making. Take your asset management to the next level with Closoft Technologies. Contact us today to learn how we can support your business.

Motion Control & Material Handling

Enhance your manufacturing efficiency with our advanced automation solutions for motion control and handling. At Closoft Technologies, we specialize in integrating cutting-edge technologies to streamline and optimize the movement and positioning of objects in industrial environments.

Key benefits:- Safety: Improve workplace safety by automating repetitive or hazardous tasks, thereby reducing the risk of accidents and injuries.

- Precision and Accuracy: Our automated systems ensure precise control over the motion and positioning of materials and components, minimizing errors and enhancing product quality.

- Speed and Efficiency: Increase throughput and reduce cycle times with fast and consistent handling processes powered by servo motors, actuators, and robotics.

- Flexibility and Adaptability: Easily adapt to varying production demands and tasks through scalable automation solutions that offer flexibility without compromising efficiency.

- Safety: Improve workplace safety by automating repetitive or hazardous tasks, thereby reducing the risk of accidents and injuries.

With a proven track record in industrial automation, we deliver reliable solutions that integrate seamlessly with your existing processes. Our expertise in motion control, robotics, and PLC programming ensures optimized performance and operational excellence.

Transform your manufacturing operations with Closoft Technologies!

Contact us today to learn more about how our automation solutions can drive productivity and competitiveness for your business.

Primary & Secondary Picking & Packing

Experience enhanced efficiency and precision in your picking and packing operations with our advanced automation solutions. At Closoft Technologies, we specialize in integrating cutting-edge technologies to streamline both primary and secondary picking and packing processes in industrial and warehouse environments.

Key benefits:- Primary Picking: Utilize automated guided vehicles (AGVs), robotic arms, or conveyor systems to efficiently pick items from shelves or storage locations. This reduces manual handling and enhances speed and accuracy.

- Secondary Packing: Automate packing processes with robotic packing stations or automated packaging machines. Our solutions ensure consistent packaging quality and optimize throughput.

- Integration and Scalability: Seamlessly integrate our automation solutions with your existing warehouse management systems (WMS) or enterprise resource planning (ERP) software. Scale operations easily to meet growing demand.

We specialize in designing and implementing customized solutions tailored to your specific needs. Our team of experts ensures seamless integration and ongoing support to maximize the performance and reliability of your automated picking and packing operations.

Transform your warehouse efficiency with Closoft Technologies!

Contact us today to discuss how our automation solutions can optimize your picking and packing processes and drive business growth

Automotive – Assembly lines

Explore our advanced automation solutions designed to optimize automotive manufacturing. At Closoft Technologies, we specialize in integrating robotics and automated guided vehicles (AGVs) to enhance assembly line efficiency and precision.

Key benefits:- Increased Productivity: Boost throughput and reduce cycle times with robotic assembly and AGV-driven logistics.

- Enhanced Quality: Ensure consistent product quality with automated inspection and assembly processes.

- Cost Efficiency: Optimize resource utilization and lower operational costs through streamlined automation

With our expertise in automotive automation, we deliver tailored solutions that improve workflow efficiency and ensure compliance with industry standards. Contact us today to learn how we can elevate your assembly line operations

Standalone EOL Machines

We continuously monitor the performance of automated systems and identify opportunities for optimization and improvement. This may involve fine-tuning control algorithms, upgrading hardware components, or implementing new technologies to stay competitive and meet evolving business needs

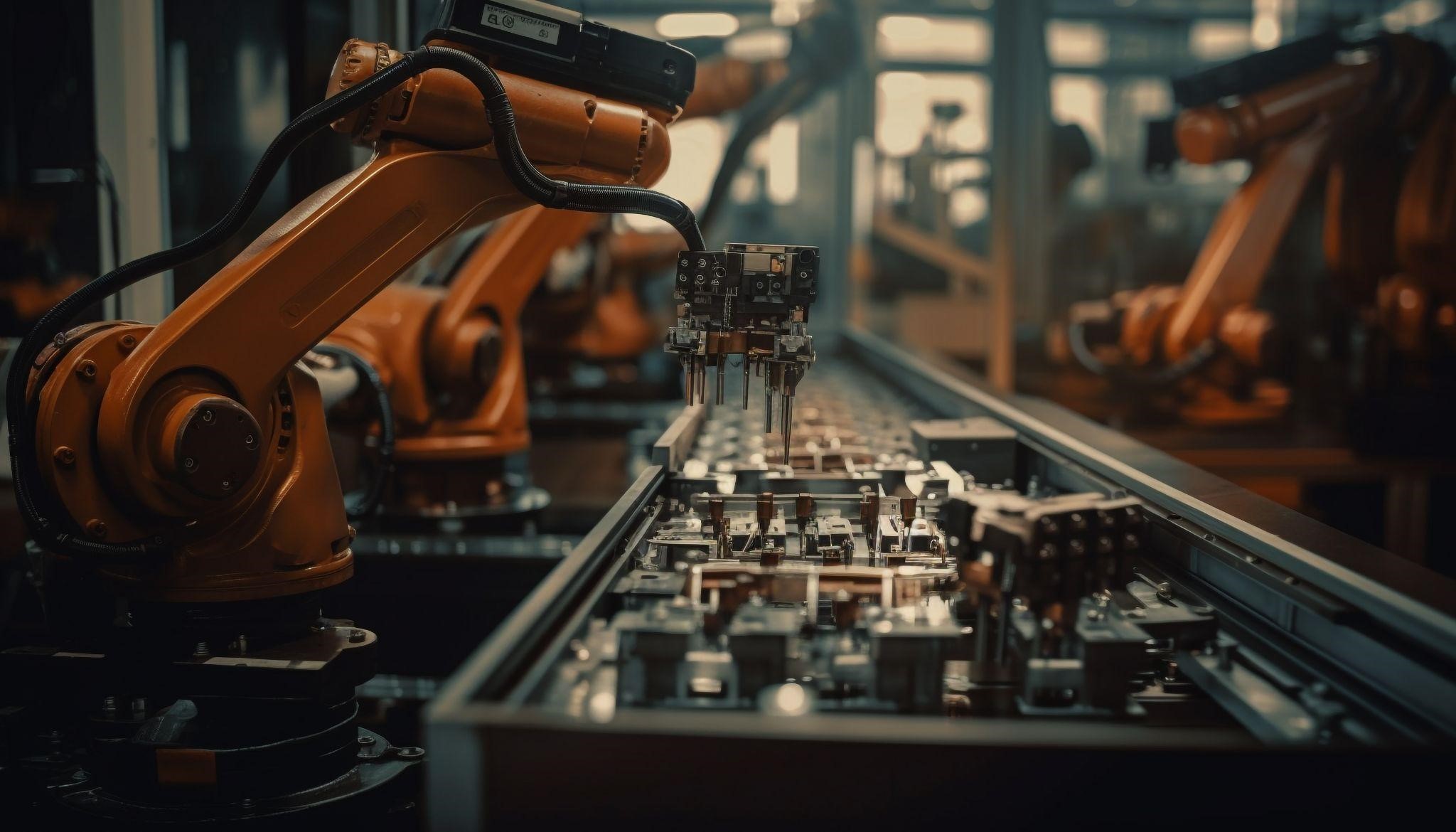

Robotic Integration

Experience seamless operational efficiency with our robust robotic integration solutions. At Closoft Technologies, we specialize in harnessing cutting-edge robotics to automate and optimize manufacturing processes across diverse industries.

We excel in designing flexible automation solutions that enhance agility and scalability, tailored to meet your specific production requirements. By leveraging our expertise in robotic integration, you can significantly increase throughput, improve product quality through precise robotic workflows, and achieve substantial cost savings by reducing labor costs and minimizing errors.